Electrical relays play a crucial role in various industries, serving as essential components in controlling and protecting electrical circuits. These devices are designed to switch and control electrical currents, ensuring the smooth and safe operation of complex systems. In this comprehensive blog post, we will delve into the fascinating realm of electrical relays, exploring the multitude of types available in the market today.

- Electromechanical Relays:

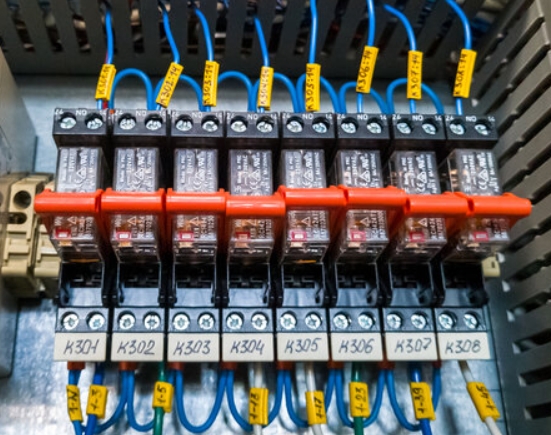

One of the most common types of relays, electromechanical relays, utilize an electromagnet to control the switching mechanism. These relays consist of a coil, armature, and contacts. When an electrical current passes through the coil, it generates a magnetic field, attracting the armature and closing the contacts. Electromechanical relays are widely used in applications that require high switching capacity and durability. - Solid-State Relays:

Unlike electromechanical relays, solid-state relays (SSRs) do not have any moving parts. Instead, they employ semiconductor devices, such as thyristors or transistors, to control the switching action. SSRs offer numerous advantages, including faster switching speeds, higher reliability, and noise-free operation. They are commonly used in applications where silent operation, long lifespan, and precise control are essential. - Reed Relays:

Reed relays are unique in their construction, utilizing a hermetically sealed glass tube containing two metal reeds and a coil. When a current passes through the coil, it generates a magnetic field, causing the reeds to attract and make contact. Reed relays are known for their compact size, low power consumption, and excellent resistance to shock and vibration. They find applications in telecommunications, test equipment, and medical devices. - Thermal Relays:

Thermal relays, also known as overload relays, are primarily used for motor protection. These relays monitor the temperature of the motor and protect it from overheating. When the motor's temperature exceeds a predetermined threshold, the thermal relay trips and interrupts the circuit, preventing damage to the motor. Thermal relays are crucial in preventing motor burnout and ensuring safe operation in industrial settings. - Time Delay Relays:

Time delay relays (TDRs) are designed to introduce a delay in the switching action. They are commonly used in applications where precise timing is required, such as motor control, lighting systems, and industrial automation. TDRs can be programmed to provide various time delays, allowing for customized control and sequencing of electrical circuits.

Conclusion:

The world of electrical relays is vast and diverse, with each type serving specific purposes in various industries. From electromechanical relays to solid-state relays, reed relays, thermal relays, and time delay relays, the options are abundant. Understanding the different types of relays and their applications is crucial for engineers, technicians, and enthusiasts working with electrical systems. By harnessing the power of these versatile devices, we can ensure the efficient and reliable operation of complex electrical circuits.