Concrete waffle (or grid) slab systems have grown in popularity due to their structural efficiency and material savings. The use of reusable waffle formwork allows for repeated cycles of casting, removal, cleaning, and reuse—significantly reducing waste and cost over time. If you are considering implementing reusable waffle formwork on your projects, this guide will help you optimize its usage. We will also reference the products and solutions offered by SUZHOU BOGUAN YUEOU INTELLIGENT EQUIPMENT CO., LTD., whose offerings provide a practical benchmark for quality systems. (See their product line here: https://www.szformwork.com/reusable-waffle-formwork-supply.html)

Understanding the Role of Waffle Formwork in Slab Construction

In traditional solid slabs, a uniform depth of concrete must be poured across the entire slab area. Waffle slabs, however, use a grid of ribs (or "waffles") underneath the slab to reduce dead load while maintaining structural strength. The top surface remains flat, but underneath there is a pattern of voids and ribs that lighten the slab.

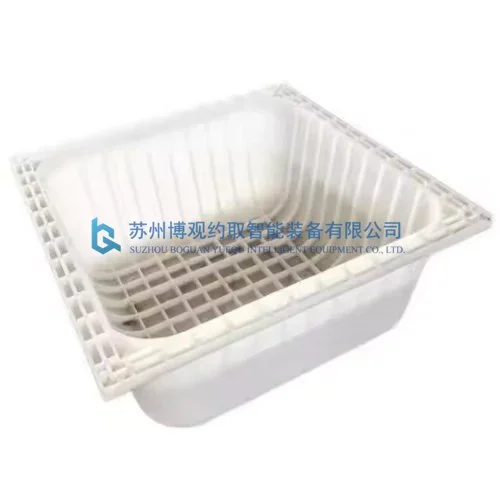

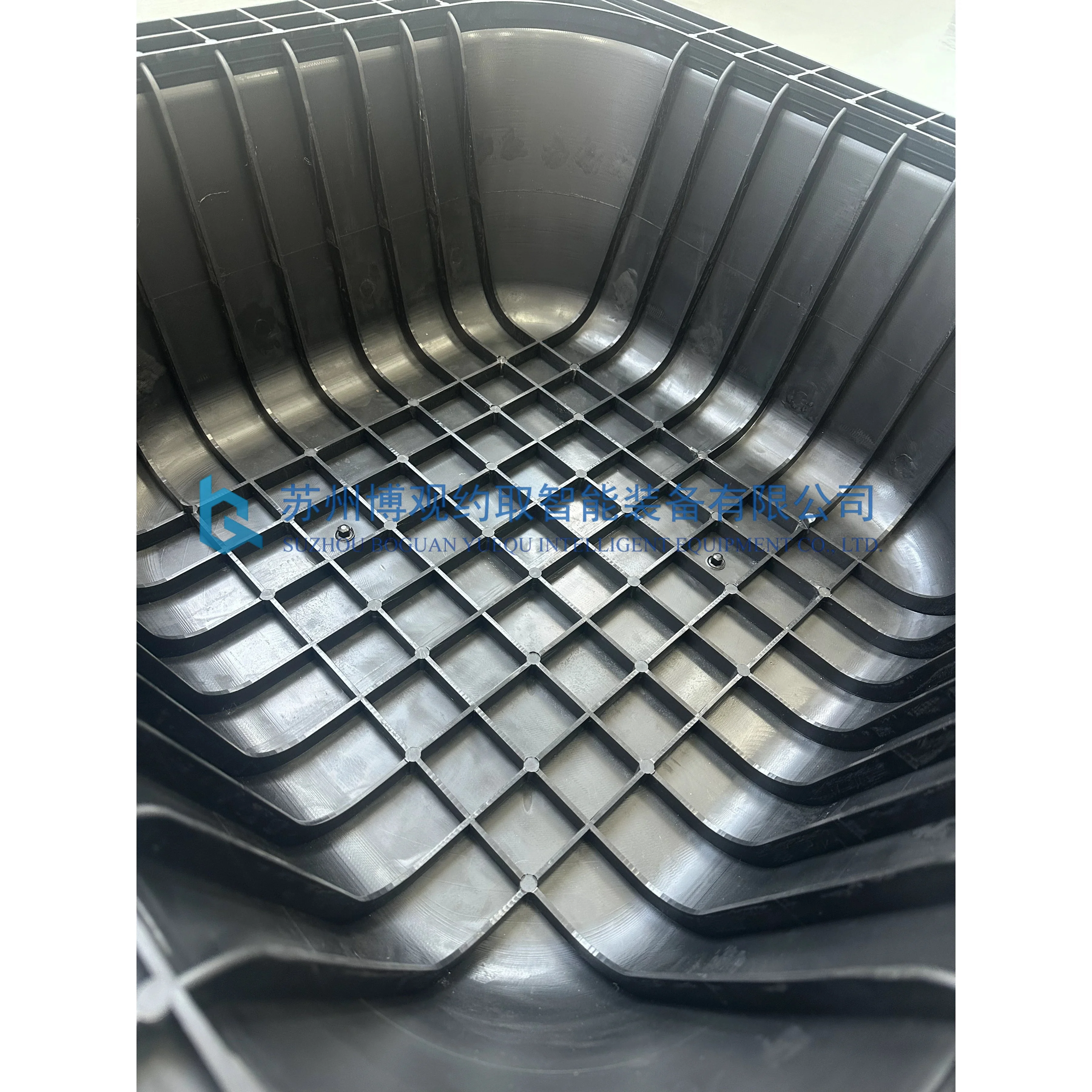

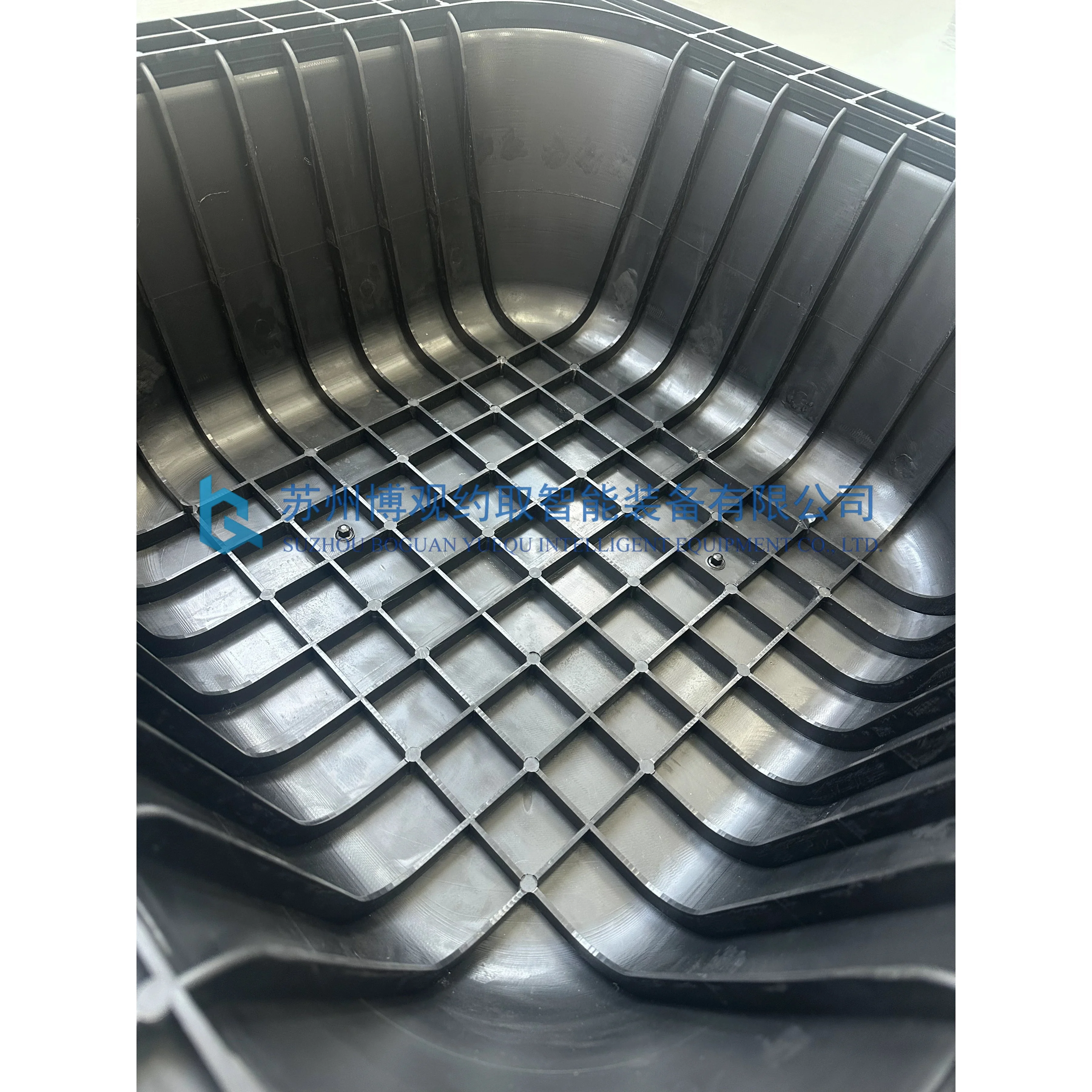

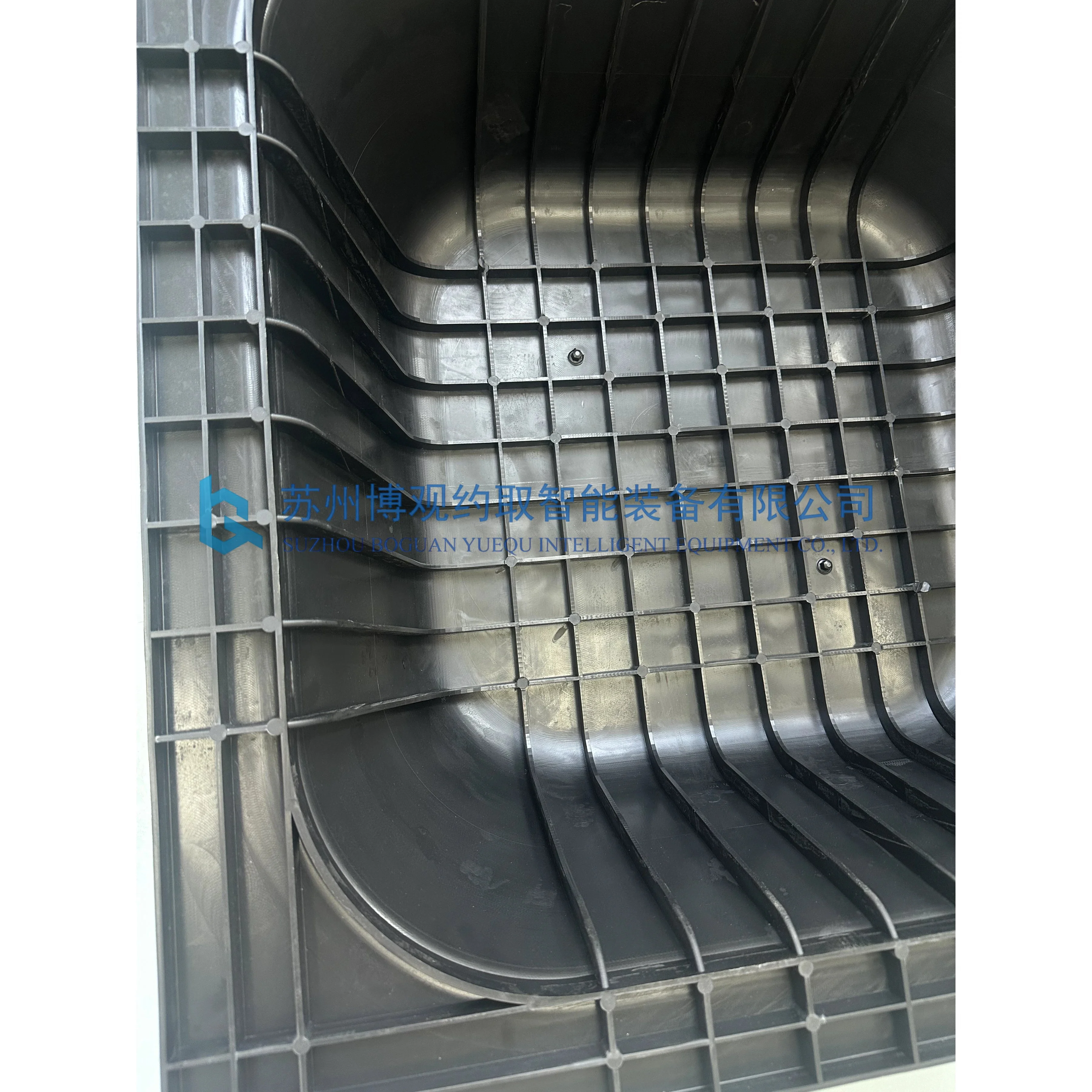

Reusable waffle formwork consists of modular molds (often plastic, ABS, or composite) that are placed on the slab reinforcement grid before concrete casting. After the concrete reaches sufficient strength, these molds are demolded, cleaned, and used again in subsequent pours. Well‑designed reusable systems can be used dozens or even over one hundred times, making them cost‑effective in high‑volume construction. Some suppliers (including many in China) advertise mold reuse rates over 100 cycles. toponew.en.made-in-china.com

Because the system is modular, it adapts well to different slab geometries, openings, and boundary conditions—if the design and planning are done properly.

Choosing the Right Reusable Waffle Formwork System

Before deployment, selecting an appropriate system is crucial. Key criteria to consider include:

Material strength and durability: High-quality polymer or composite molds resist deformation, UV, abrasion, and chemical exposure over repeated use.

Dimensional tolerance and finish: Molds must produce consistent rib heights and clean surfaces to ensure correct concrete depth and finish quality.

Ease of demolding and stripping: Systems that allow simple release (without requiring heavy machinery) speed up cycle times.

Modularity and adaptability: Ability to customize mold layouts, accommodate openings, and nest molds for storage.

Service life and warranty: Reputable systems typically support dozens to over a hundred reuse cycles.

Support, spare parts, and logistics: The supplier should offer spare modules, accessories, and responsive service. SUZHOU BOGUAN YUEOU, for example, positions itself as a full‑service supplier with intelligent formwork solutions. Global Sources

When evaluating the offering from SUZHOU BOGUAN YUEOU (via their website), check the technical specifications—rib height tolerances, recommended demolding time, cleaning protocols, and expected number of cycles. Their product line offers one reference for what a mature supplier provides.

Planning and Layout for Efficient Use

To maximize efficiency, careful planning is essential. Some best practices include:

Design the slab ribs and module layout early: Integrate formwork layout into the structural design so modules align with columns, openings, and beams.

Minimize module cuts and irregular shapes: Keeping the mold layout as regular as possible reduces time for adjustments and waste.

Account for reinforcement clearance and access: Ensure the mold installation sequence does not conflict with rebar work or embedding utilities.

Optimize logistics and staging: Preassemble or pre‑dry modules before delivery to site. Use storage racks that allow easy movement.

Schedule demolding, cleaning, and rotation: Plan for a workflow where demolded panels go directly to cleaning, inspection, and staging for the next pour.

Proper planning reduces idle time, lowers labor costs, and minimizes damage to molds from handling errors.

Best Practices During Casting and Demolding

The actual casting, setting, and stripping process can strongly influence durability and finish. Follow these recommendations:

Ensure proper concrete mix and slump control: Excessively fluid concrete may cause leaks or seeping under molds, while low workability may lead to honeycombing.

Use vibration carefully: Excessive vibration can damage or misalign mold modules. Use vibration settings that transmit to the ribs and slab without dislodging the molds.

Control setting time before demolding: Only demold when concrete has reached the minimum required strength to avoid surface damage or cracks.

Strip molds gently and in the correct sequence: Begin from edges, gradually lift the molds, and avoid prying or twisting, which can deform or crack modules.

Inspect molds immediately after removal: Before stacking, check for any cracks, deformations, or adhered concrete that must be removed.

Maintenance, Cleaning, and Storage for Longevity

One of the keys to a long service life is disciplined maintenance of the reusable molds. Here are proven practices:

Immediate cleaning after demolding: Remove residual concrete before it fully cures, using soft brushes and mild agents. Avoid sharp metal scraping.

Inspect for damage: Check for cracks, chips, or wear. Mark modules that are approaching end‑of‑life and remove them from full duty.

Store in dry, shaded conditions: UV light, heat, or moisture can degrade polymers over many cycles.

Rotate module usage: Avoid repeatedly using the same molds in the same positions; rotate modules to even out wear.

Repair minor damage: Some systems allow patching or refurbishment of modules to extend life.

Track usage cycles: Maintain a log for each module, recording casts, inspections, and maintenance history.

Adhering to these practices helps the molds reach or exceed their expected reuse count.

Overcoming Common Challenges and Pitfalls

In practice, users may encounter issues. Here is how to mitigate them:

Warped or out-of-flat molds: Use strict tolerances and avoid exposure to extreme heat or uneven stacking.

Concrete “bleeding” beneath molds: Improve sealing via gaskets or foam strips; adjust concrete consistency.

Sticking or difficulty in stripping: Apply parting agents or lubricant to mold surfaces, and ensure modular joints are tight.

Uneven concrete compaction in ribs: Fine-tune vibration strategy or adjust mold reinforcement spacing.

Module wear in high-stress zones: Use reinforced modules or replace modules proactively in heavily loaded areas.

By anticipating these challenges, you can reduce downtime and extend system life.

Case Use and Cost Savings Over Time

A well‑implemented reusable waffle formwork system can deliver substantial savings. Because modules are used repeatedly, the amortized cost per pour drops. In large projects (e.g. multi‑story buildings or repeated floor slabs), the system pays for itself. Additionally:

Material savings: Less concrete is needed compared to solid slabs due to the rib configuration.

Reduced formwork waste: No single-use timber or plywood is discarded after each pour.

Faster cycles: With efficient demolding and cleaning, turnaround per floor speeds up.

Improved finish: Uniform surfaces and mold quality reduce remedial finishing time.

Clients who adopt quality formwork systems from reliable suppliers like SUZHOU BOGUAN YUEOU benefit from full support in logistics, training, and spare parts, helping ensure successful implementation.