When it comes to vehicle recovery, especially for trucks operating in demanding environments, the choice of recovery equipment can make the difference between a safe, controlled pull and a dangerous failure. Among all recovery tools, truck recovery straps play a critical role—and the material they are made from is one of the most important factors affecting performance.

Two materials dominate the market: nylon and polyester. At first glance, they may appear similar, but in real-world recovery scenarios, their behavior, durability, and safety characteristics are significantly different.

This article provides a comprehensive, practical comparison of nylon vs polyester truck recovery straps, helping fleet managers, off-road enthusiasts, industrial users, and procurement professionals make informed decisions based on actual application needs rather than marketing claims.

1. Understanding Truck Recovery Straps

Truck recovery straps are heavy-duty woven straps designed to recover stuck or disabled vehicles. Unlike chains or steel cables, recovery straps are lightweight, flexible, and easier to handle, while also reducing the risk of dangerous recoil when properly used.

They are commonly used in:

Off-road vehicle recovery

Construction and mining sites

Agricultural operations

Emergency roadside assistance

Military and industrial vehicle recovery

The material composition of a recovery strap directly influences:

Stretch behavior

Energy absorption

Resistance to abrasion, UV, and moisture

Overall service life and safety margin

2. What Are Nylon Truck Recovery Straps?

2.1 Material Characteristics of Nylon

Nylon is a synthetic polyamide fiber known for its high elasticity, excellent tensile strength, and energy absorption capacity. These properties make nylon a popular choice for dynamic recovery situations.

Key characteristics include:

High elongation (typically 15–30%)

Strong shock-load absorption

Soft, flexible hand feel

Good resistance to repeated loading

2.2 How Nylon Recovery Straps Perform in Use

Because nylon stretches significantly under load, it acts like a rubber band, storing kinetic energy and releasing it gradually during recovery. This makes nylon straps particularly suitable for snatch recovery, where a moving vehicle assists in pulling out a stuck one.

Advantages:

Reduced peak load on vehicle recovery points

Smoother, controlled recovery

Lower risk of sudden jerk forces

However, this elasticity can also become a disadvantage in certain scenarios, which we’ll explore later.

3. What Are Polyester Truck Recovery Straps?

3.1 Material Characteristics of Polyester

Polyester is another synthetic fiber, widely used in lifting slings, cargo tie-downs, and industrial webbing due to its low stretch, dimensional stability, and excellent environmental resistance.

Typical characteristics include:

Low elongation (usually 5–10%)

High abrasion resistance

Superior UV and moisture resistance

Stable performance under constant load

3.2 How Polyester Recovery Straps Perform in Use

Polyester straps provide a more direct pull, transferring force with minimal stretch. This makes them ideal for controlled towing or static recovery, where precision and stability matter more than shock absorption.

Advantages:

Predictable force transmission

Minimal rebound or snap-back

Better performance in wet or UV-exposed environments

4. Stretch and Energy Absorption: The Core Difference

Nylon: High Stretch, High Energy Absorption

Nylon’s ability to stretch allows it to:

Absorb kinetic energy

Reduce stress on vehicle frames and attachment points

Improve success rates in mud, sand, or snow recovery

However:

Excessive stretch can create recoil hazards if the strap or anchor point fails

Requires greater operator skill and safety awareness

Polyester: Low Stretch, High Control

Polyester straps:

Transmit force more directly

Offer better control for slow, steady pulls

Reduce risk of uncontrolled snap-back

But:

They do not absorb shock loads as effectively

Sudden jerks can stress recovery points if used incorrectly

5. Strength Ratings and Load Stability

Both nylon and polyester straps can be manufactured with high breaking strengths, often exceeding 20,000–30,000 lbs for heavy-duty truck applications.

However, their behavior under load differs:

Nylon straps may temporarily elongate under load but return to original length if not overloaded.

Polyester straps maintain consistent length, making them preferable for operations requiring stable positioning.

For applications involving frequent static loads, polyester generally maintains strength more consistently over time.

6. Environmental Resistance and Durability

Moisture and Water Exposure

Nylon absorbs water, which can temporarily reduce strength and increase stretch.

Polyester is hydrophobic, maintaining strength even when wet.

This makes polyester better suited for:

Marine environments

Snow and ice recovery

Humid or rainy climates

UV Resistance

Nylon degrades faster under prolonged UV exposure.

Polyester offers superior UV resistance, making it more suitable for outdoor storage and long-term exposure.

Abrasion Resistance

Both materials are abrasion-resistant, but polyester typically performs better on rough surfaces such as rocks, gravel, or concrete.

7. Safety Considerations in Real-World Recovery

Safety is one of the most critical factors when choosing a recovery strap.

Nylon Safety Considerations

Higher stored energy increases recoil risk if failure occurs

Requires strict adherence to safety protocols

Best used with rated recovery points and experienced operators

Polyester Safety Considerations

Lower recoil risk due to minimal stretch

Easier for inexperienced users to control

Often preferred by roadside assistance and fleet operators

8. Application-Based Recommendations

Choose Nylon Truck Recovery Straps If:

You perform off-road or snatch recovery

Vehicles are deeply stuck in mud or sand

Shock load absorption is critical

Operators are trained and safety-aware

Choose Polyester Truck Recovery Straps If:

You need controlled towing or static recovery

Operating in wet, UV-exposed, or harsh environments

Consistency and predictability matter

Used by fleets, commercial operators, or roadside services

9. Cost and Long-Term Value

Nylon straps often cost slightly more due to material properties and weaving requirements. However, their performance benefits can justify the cost in dynamic recovery situations.

Polyester straps may offer:

Longer service life in harsh environments

Lower maintenance requirements

Better ROI for commercial and industrial users

10. OEM, Wholesale, and Custom Manufacturing Considerations

For OEM buyers and bulk purchasers, material choice affects:

Product positioning (off-road vs industrial)

Compliance with safety standards

Branding and customer education

Many professional manufacturers offer:

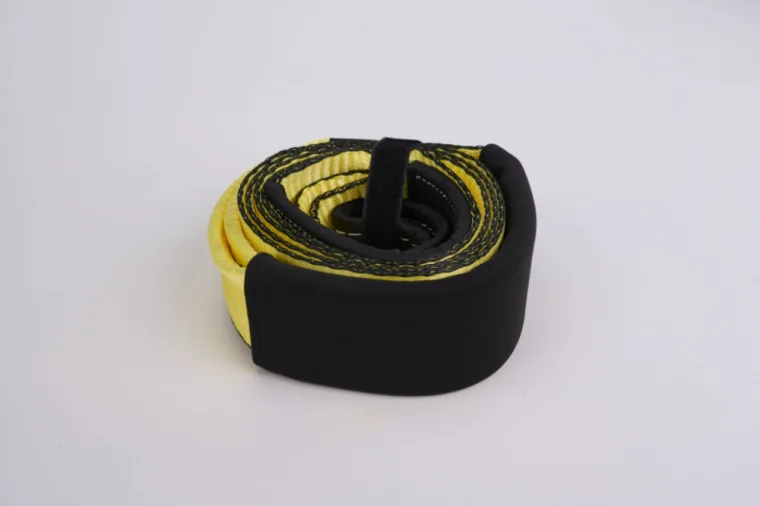

Custom lengths and widths

Reinforced eye loops

Protective sleeves

Private labeling and packaging

Choosing the right material ensures alignment with target market expectations.

11. Final Verdict: Nylon or Polyester?

There is no universally “better” option—only the right tool for the right job.

Nylon truck recovery straps excel in dynamic, high-energy recoveries where elasticity improves success and protects vehicles.

Polyester truck recovery straps shine in controlled, predictable recovery scenarios where durability, safety, and environmental resistance are priorities.

Understanding how each material behaves under real-world conditions allows you to choose a recovery strap that delivers maximum performance, safety, and value.

Conclusion

When selecting a truck recovery strap, focusing solely on breaking strength is not enough. The material—nylon or polyester—defines how the strap behaves, how safe it is, and how long it will last.

By matching material characteristics to your recovery scenarios, environment, and operator skill level, you ensure safer recoveries, reduced equipment damage, and greater operational efficiency.

Choosing wisely today means fewer failures—and safer recoveries—tomorrow

www.reliablesling.com

reliablesling