In modern laboratories, accuracy is no longer determined by detection alone. The reliability of assay results often depends on what happens before a microplate ever reaches the reader. One of the most critical yet frequently underestimated steps in this process is plate washing.

A microplate washer automates the removal of unbound reagents—such as antibodies, enzymes, or residual media—from 96-well plates. By controlling wash volume, speed, and cycle consistency, it helps eliminate background interference and ensures that downstream optical density (OD) or fluorescence readings reflect true signal rather than noise.

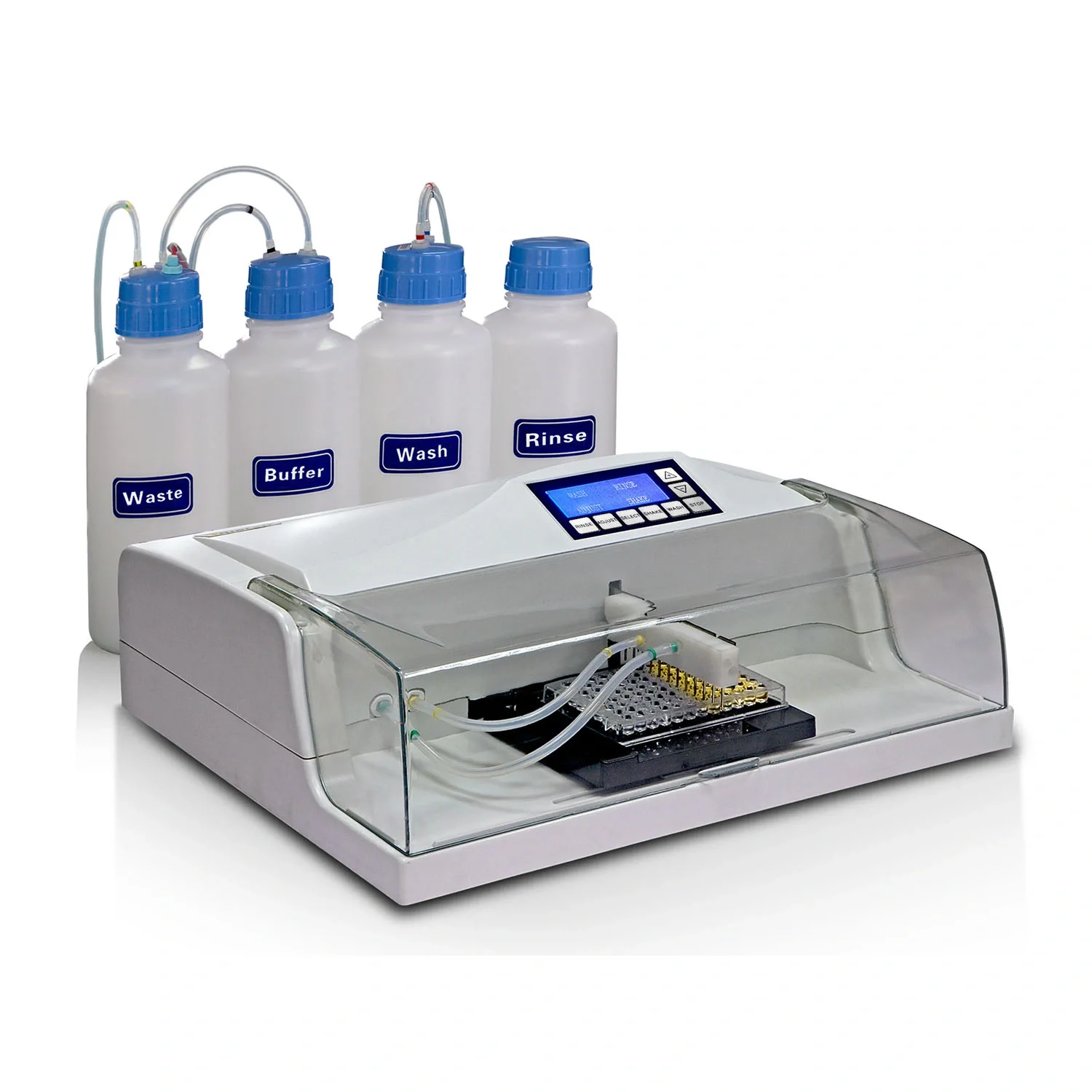

The Microplate Washer DRW-310 from Diatek is designed specifically to support precision-driven workflows where reproducibility and throughput are equally important.

The hidden impact of poor washing on assay quality

In many assays, especially immunoassays and cell-based tests, washing quality directly affects signal clarity. Inconsistent or manual washing can lead to:

Residual unbound antibodies increasing background signal

Uneven reagent removal between wells

Cross-contamination caused by splashing or inconsistent aspiration

Reduced repeatability between runs or operators

These issues often appear later as unexplained data variation, failed controls, or low signal-to-noise ratios—problems that are difficult to trace back once detection has already taken place.

Automated microplate washing addresses these risks by standardizing one of the most error-prone steps in the workflow.

What a microplate washer actually does in practice

At its core, a microplate washer performs three essential tasks:

Dispenses wash buffer into each well at a controlled volume and speed

Allows sufficient contact time for effective removal of unbound materials

Aspirates liquid uniformly, minimizing residual volume and carryover

The DRW-310 supports programmable wash parameters, enabling users to define wash volume, aspiration speed, and number of cycles based on assay requirements. This flexibility is critical when switching between different protocols or assay types within the same laboratory.

Why automation matters more in high-throughput environments

In low-volume labs, manual washing might seem manageable. However, as throughput increases, manual methods quickly become a bottleneck and a source of variability.

In high-throughput laboratories, a microplate washer offers clear advantages:

Consistent processing across large plate batches

Reduced operator fatigue and handling errors

Predictable cycle timing that supports scheduling

Easier standardization across multiple users or shifts

When paired with a microplate reader, the washer becomes part of a streamlined washer → reader workflow, improving both efficiency and data consistency.

Integration with microplate readers: a workflow perspective

Microplate washers are rarely standalone instruments. Their value is maximized when integrated smoothly into a broader analytical workflow.

The DRW-310 is designed to work seamlessly ahead of microplate readers in applications such as:

ELISA testing, where accurate post-wash detection of biomarkers depends on clean well surfaces

Drug screening, especially cell-based assays requiring careful removal of excess compounds before OD or fluorescence reading

Clinical diagnostics, where automated washing improves consistency prior to reader analysis

High-throughput screening labs, where speed and repeatability are critical

By ensuring that plates arrive at the reader in a consistent state, the washer protects the integrity of the detection step.

Controlling cross-contamination and background interference

One of the most common concerns in multi-well assays is cross-contamination between wells. Even minor liquid carryover can compromise results, particularly in sensitive assays.

Automated microplate washers reduce this risk by:

Using controlled aspiration paths

Maintaining consistent dispense and suction speeds

Applying repeatable wash cycles across all wells

These controls help minimize residual reagents and reduce well-to-well variability, contributing to cleaner baselines and more reliable signal differentiation.

Programmability: adapting to different assay demands

Not all assays wash the same way. Some require gentle handling to preserve cells, while others demand aggressive washing to fully remove unbound reagents.

A programmable washer allows laboratories to:

Store multiple wash protocols

Adjust parameters without mechanical changes

Switch quickly between assay types

This adaptability is particularly valuable in shared labs, contract research organizations, and diagnostic facilities where workflows change frequently.

Reducing operator dependency in regulated environments

In clinical and regulated laboratory settings, reducing operator-dependent variability is a priority. Automated washing helps support compliance by:

Standardizing wash procedures

Improving repeatability between runs

Simplifying method validation and documentation

When washing becomes a controlled, programmable process rather than a manual technique, data integrity is easier to maintain over time.

Where microplate washers deliver the most value

Microplate washers are especially valuable in laboratories that perform:

Routine ELISA testing

Large-scale drug screening

Diagnostic assays with strict quality requirements

High-throughput research requiring consistent plate processing

In these environments, the washer is not just a convenience—it is a critical quality control tool.

www.hiwelldiatek.com

Wuxi Huawei Diatek Instrument Co., Ltd.