Disc springs, also known as disc springs, are typically made from metal strips, plates, or forged blanks. They are a type of truncated cone spring with high stiffness and variable stiffness characteristics.

1.1 Structure of a common disc spring

Ordinary disc springs have been standardized, and their design and manufacturing can refer to GB/T1972.

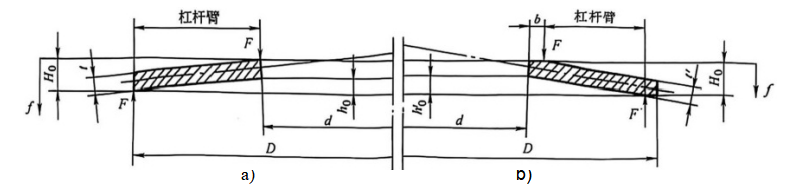

1) Disc springs come in two forms depending on their support structure: one is a disc spring without a support surface (Figure 17-1a), where the upper inner edge and the lower outer edge are not machined, so the load-bearing part has no support plane; the other is a disc spring with a support surface (Figure 17-1b), where the inner and outer edges are machined to form a support surface, and the load is applied to the support surface.

Figure 17-1 Structural form of a common disc spring

a) Disc spring without support surface b) Disc spring with support surface

2) Disc springs are classified into three types and structural forms according to their thickness t value, as shown in Table 17-2.

Table 17-2 Categories and Structural Types of Disc Springs (Unit: mm)

Type | Thickness | Support surface and thinning thickness | Type | Thickness | Support surface and thinning thickness |

1 2 | ≤1.25 1.25~6 | None, see Figure 17-1a None, see Figure 17-1a | 3 | >6.0~14.0 | Yes, see Figure 17-1b. |

3) The dimensions and parameters of disc springs are divided into three series: A, B, and C, based on the values of D/t and h₀/t.

4) Disc spring series markings.

D×d×t×H₀ Precision requirement

Technical requirements should be filled in according to the following provisions: Refer to GB/T 1972, fill in the accuracy grade, and add a letter before the accuracy grade.

“C”。

For example :

A first-precision disc spring with an outer diameter of φ500, an inner diameter of φ253, a thickness of 18 mm, a thinning thickness of 16.6 mm, and a free height of 31.5 mm is marked as: φ500×φ253×18×31.5—C1.

A second-precision disc spring with the same outer diameter of φ500, inner diameter of φ253, a thickness of 18 mm, a thinning thickness of 16.6 mm, and a free height of 31.5 mm is marked as: φ500×φ253×18×31.5—C2.

1.2 Characteristics of Disc Springs

1) It has a small size in the direction of load application and can withstand large loads with very small deformations, resulting in a compact axial space. Compared with other types of springs, its deformation energy per unit volume of material is larger. It has good damping and vibration absorption capabilities, especially when using stacked spring assemblies, where the absorption of impact and dissipation of energy is more significant due to surface friction damping.

2) It has variable stiffness characteristics. Changing the ratio of the height h of the truncated cone inside the disc to the thickness t of the disc can yield different spring characteristic curves, which can be linear, gradually increasing, gradually decreasing, or a combination thereof. Furthermore, variable stiffness characteristics can be obtained by combining discs of different thicknesses or by combining discs of different numbers.

3) Because different load-bearing capacities and characteristic curves can be obtained by changing the number of discs or the combination of discs, each size of disc can adapt to a wide range of applications, making spare parts preparation and management easier.

4) In combined springs that bear large loads, the size of each disc is small, which is beneficial for manufacturing and heat treatment. When some discs are damaged, only individual replacements are needed, thus facilitating maintenance and repair. 5) Properly designed and manufactured disc springs have a long service life.

6) Because the inner cone height *h* and disc thickness *t* significantly affect spring characteristics, disc springs require high manufacturing quality, limiting their wider application. Even with a uniform cross-section, the stress distribution within the disc spring's cross-section is uneven, thus affecting its fatigue strength and vibration absorption capacity per unit volume.

Disc springs are commonly used in heavy machinery (such as large forging presses, boiler hangers, etc.), aircraft, artillery, and other machines or weapons as powerful buffers and vibration dampers; they are also used as pressure springs in clutches or safety valves and pressure reducing valves in automobiles and tractors; they are also used in control mechanisms of automated devices; and they are used as elastic washers in bolted connections.

www.raleigh-springs.com

Raleigh Spring Technology Co., Ltd.