Mechanical seals are an essential component in many industrial applications, including pumps, compressors, and mixers. They are used to prevent leakage of fluids and gases from the equipment, ensuring safe and efficient operation. In this article, we will explore what mechanical seals are, how they work, and their importance in various industries.

What is a Mechanical Seal?

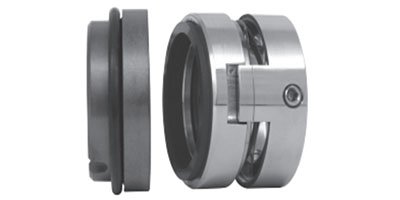

A mechanical seal is a device that seals the gap between two surfaces, preventing the escape of fluids or gases. It consists of two main components: a stationary part and a rotating part. The stationary part is typically mounted on the equipment housing, while the rotating part is attached to the shaft of the equipment.

How Does a Mechanical Seal Work?

When the equipment is in operation, the rotating part of the mechanical seal rotates with the shaft, while the stationary part remains fixed. The two parts are held together by a spring, creating a seal that prevents the escape of fluids or gases.

The Importance of Mechanical Seals

Mechanical seals are critical components in many industrial applications, as they prevent leakage of hazardous or expensive fluids and gases. They also help to reduce maintenance costs and downtime by extending the lifespan of equipment. In addition, mechanical seals can improve energy efficiency by reducing the amount of fluid or gas that escapes from the equipment.

Applications of Mechanical Seals

Mechanical seals are used in a wide range of industrial applications, including pumps, compressors, mixers, and agitators. They are commonly used in the chemical, oil and gas, pharmaceutical, and food and beverage industries, among others.

In the chemical industry, mechanical seals are used to prevent the escape of hazardous chemicals, ensuring the safety of workers and the environment. In the oil and gas industry, mechanical seals are used to prevent the escape of oil and gas from pipelines and equipment, reducing the risk of environmental damage and ensuring efficient operation. In the pharmaceutical industry, mechanical seals are used to prevent contamination of drugs and other products, ensuring their safety and efficacy.

Conclusion

Mechanical seals are essential components in many industrial applications, preventing the escape of fluids and gases and ensuring safe and efficient operation. They are used in a wide range of industries, including chemical, oil and gas, pharmaceutical, and food and beverage. By understanding the importance of mechanical seals and their applications, companies can ensure the safety of their workers, protect the environment, and improve the efficiency of their operations.