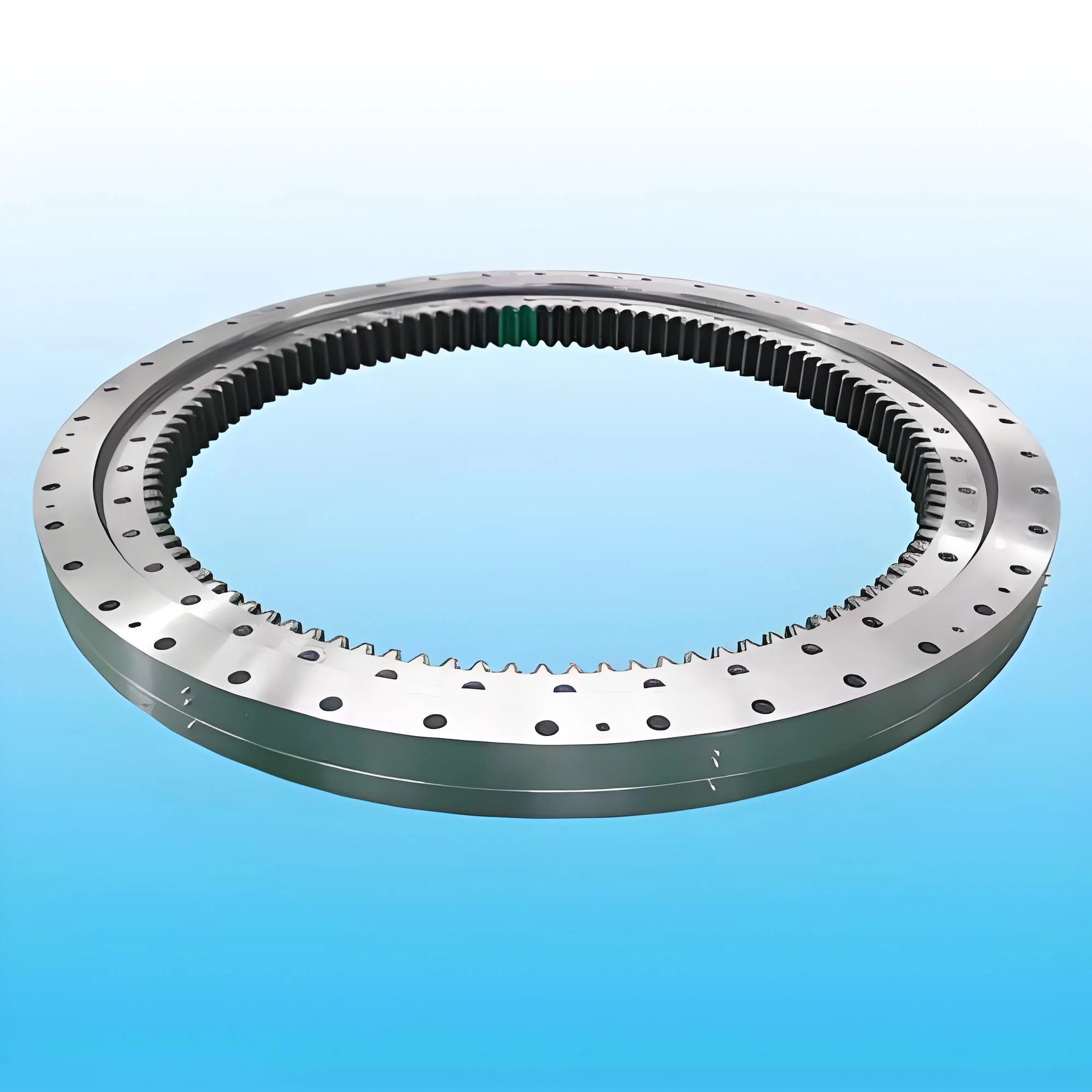

In industrial machinery and heavy equipment systems, slewing bearings are the unsung heroes. They support massive loads, allow precise rotational movement, and endure challenging operating conditions. From chemical reactors to fermentation equipment and large-scale conveyors, slewing bearings are critical components that must be chosen with care.

At Sawei Equipment Technology, a company that specializes in the development of complete process equipment solutions for industries such as phosphorus and sulfur-based fertilizer production, compound fertilizers (like SOP), and carbon-based industrial recycling, equipment performance is non-negotiable. This is why the quality of slewing bearings used in our systems is paramount.

In this article, we explain why quality matters and highlight the key factors to consider when purchasing slewing bearings—especially for demanding industrial applications.

1. Load Capacity and Structural Integrity

The first and most obvious factor is the load-bearing capability. Slewing bearings must support axial, radial, and moment loads—sometimes simultaneously. In chemical or fertilizer plants where massive mixers or reactors operate under high pressure and weight, any failure can be catastrophic.

Always verify:

Static and dynamic load ratings

Fatigue resistance

Design safety factors

Sawei Equipment Technology works only with bearing suppliers that meet strict international standards, ensuring all components used in our systems maintain structural integrity under heavy-duty conditions.

2. Material Quality and Heat Treatment

High-grade alloy steel and proper heat treatment processes (like quenching and tempering) are essential to achieve hardness, toughness, and wear resistance. Poor material quality or inadequate hardening can result in premature bearing failure, costly downtime, and increased maintenance.

Quality bearings undergo:

Ultrasonic testing

Hardness inspections

Surface finishing controls

At Sawei, we insist on traceable material sourcing and rigorous quality audits to ensure long-term equipment reliability.

3. Sealing and Protection from Contaminants

In sectors like phosphate chemical processing or industrial waste recovery, slewing bearings are often exposed to corrosive environments, dust, and high humidity. Without robust sealing systems, contaminants can enter the bearing assembly and degrade performance.

Look for bearings with:

Integrated dust and water-resistant seals

Corrosion protection coatings

Optional grease fittings for sealed lubrication

Sawei’s equipment design incorporates bearing protection systems customized for harsh environments, significantly extending component lifespan.

4. Precision and Rotational Accuracy

In applications involving fermentation tanks or precise dosing systems, smooth rotation and low backlash are crucial. Even small misalignments or uneven loads can reduce product quality or damage surrounding equipment.

Check for:

ISO or DIN tolerances

Runout accuracy

Turntable precision balance

We collaborate with precision engineering partners to ensure the rotational parts in Sawei’s systems meet the operational accuracy required by complex industrial processes.

5. Compatibility with Equipment Design

The slewing bearing must match the mechanical design of the entire system. This includes flange sizes, bolt hole patterns, torque transfer capacity, and mounting methods. Customization is sometimes necessary for specific projects.

Sawei Equipment Technology’s engineering team integrates slewing bearing selection into the full design process of our turnkey equipment solutions, ensuring seamless compatibility and reliable performance.

6. Supplier Reputation and After-Sales Support

Finally, choose bearings from manufacturers with a proven track record, strong technical support, and the ability to deliver replacements or spares quickly. This is particularly critical for continuous process industries, where downtime equals lost revenue.

We maintain long-term partnerships with trusted bearing manufacturers and offer ongoing support throughout the equipment lifecycle, from commissioning to maintenance.

Why Quality Drives Operational Success

In large-scale industrial systems, low-cost or poor-quality slewing bearings can result in unexpected breakdowns, dangerous failures, and massive operational losses. For companies in sectors like fertilizer production, sulfur/phosphate processing, or bio-fermentation, every component—especially critical rotating parts—must meet the highest standards.

At Sawei Equipment Technology, we know that durable, precise, and high-performance slewing bearings are essential to the success of our turnkey process solutions. That’s why we don’t compromise when it comes to quality—neither should you.

Final Thoughts

When selecting slewing bearings for your industrial application, consider not just the price, but the total value—including safety, lifespan, compatibility, and long-term reliability. Work with partners like Sawei Equipment Technology, who understand the technical and operational demands of your industry, and who integrate quality assurance at every stage of the equipment lifecycle.

Looking to optimize your equipment with reliable, high-quality components? Contact Sawei today to learn how our complete process equipment solutions are engineered for performance, safety, and sustainability.

www.swasps.com

Jiangsu Sawei Equipment Technology Co., Ltd.