https://www.ylyhmold.com/Precision-in-Injection-Molds-for-Medical-Materials.html

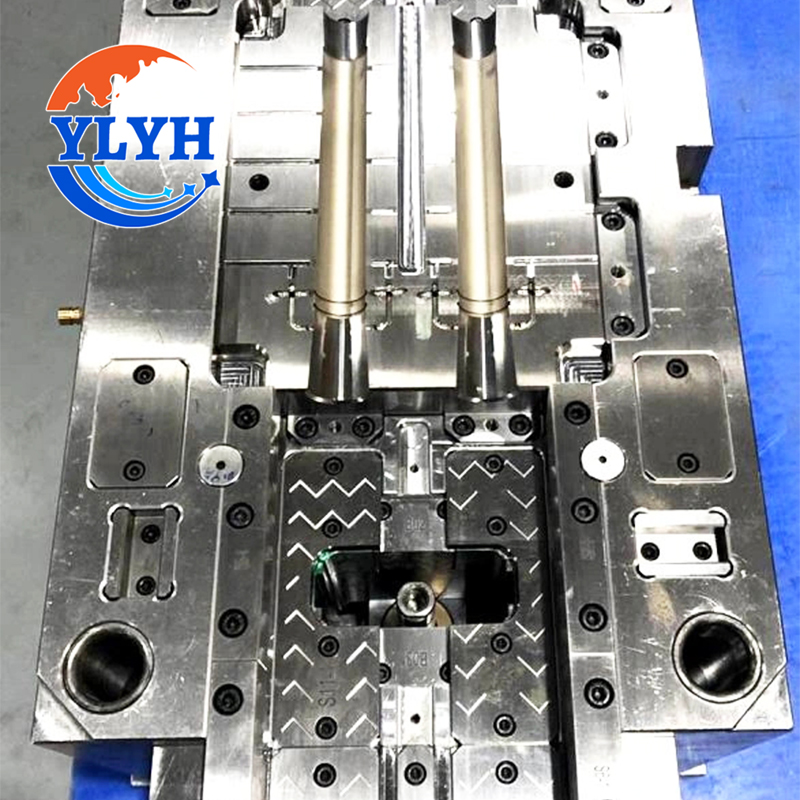

The medical industry demands absolute precision, reliability, and safety in every component. From syringes and surgical instruments to diagnostic devices and implantable components, the performance of medical devices is closely tied to the quality of their manufacturing. At the heart of this process lies injection molds for medical materials, which enable the large-scale production of consistent, safe, and biocompatible medical-grade parts. Shenzhen YLYH Technology Co., Ltd. specializes in advanced mold solutions designed to meet the strict requirements of the healthcare sector.

Design Requirements for Injection Molds for Medical Materials

Designing injection molds for medical materials requires much higher standards compared to general industrial molds. Every aspect of the mold design directly affects the performance and safety of medical devices.

1. High Precision and Tight Tolerances

Medical parts must achieve extremely tight tolerances, often down to microns. Injection molds for medical materials are engineered to replicate fine details with perfect accuracy, ensuring reliable functionality in sensitive applications such as surgical devices and diagnostic kits.

2. Complex Geometries

Many medical components feature thin walls, intricate channels, or delicate geometries. High-performance CAD software and simulation analysis are applied in mold design to ensure injection molds for medical materials can reproduce these shapes without defects or structural weaknesses.

3. Material Compatibility

Common medical-grade plastics include polypropylene (PP), polycarbonate (PC), and PEEK. Injection molds for medical materials must be designed to withstand the physical and thermal stresses of these materials, while ensuring biocompatibility and preventing contamination.

4. Compliance with Standards

Strict standards such as ISO 13485, FDA regulations, and GMP guidelines govern the medical manufacturing process. Injection molds for medical materials must therefore not only meet dimensional accuracy but also align with global requirements for cleanliness, sterilization, and material traceability.

Manufacturing Process of Injection Molds for Medical Materials

The manufacturing process of injection molds for medical materials involves multiple steps to ensure flawless results.

1. Drying of Plastic Pellets

Moisture can cause serious defects in medical parts. Before molding, pellets are dried under controlled conditions to ensure reliable performance.

2. Melting and Mixing

Plastic pellets are melted inside the injection molding machine and homogenized by a screw system. This guarantees a stable material flow so injection molds for medical materials produce parts without voids or incomplete fillings.

3. Filling, Cooling, and Demolding

The molten material is injected into the mold cavity under precise pressure and temperature controls. After cooling, the part solidifies, maintaining its accuracy. The mold then releases the part without deformation, ensuring consistency in every cycle.

Ensuring Quality in Injection Molds for Medical Materials

Quality assurance is a cornerstone of medical manufacturing. Various methods are used to verify the performance of injection molds for medical materials:

Non-destructive testing (NDT): Ensures no hidden defects within molded components.

Ultrasonic inspection: Detects internal irregularities in both molds and parts.

Surface finish control: Guarantees smooth surfaces to prevent bacterial growth and allow easier sterilization.

Dimensional measurement: Confirms that every part meets the required tolerances

The production of injection molds for medical materials combines engineering precision, strict compliance, and advanced manufacturing. From designing for complex geometries to ensuring flawless execution in molding cycles, every stage is critical to the reliability of medical devices.

At Shenzhen YLYH Technology Co., Ltd., we provide cutting-edge solutions in injection molds for medical materials, helping the healthcare industry produce safe, accurate, and consistent products. With our expertise, clients can trust that every mold meets the highest standards of precision and medical compliance.

www.ylyhmold.com

Shenzhen YLYH Technology Co., Ltd.