Electrical safety is no longer just a regulatory requirement—it has become a core design principle for modern power systems. As industries, commercial buildings, and infrastructure projects grow more complex, the risks associated with electrical faults, fire hazards, and maintenance errors also increase. In this context, dry type transformers have emerged as a safer and more reliable alternative to traditional oil-filled transformers, especially in environments where safety, environmental responsibility, and operational continuity are critical.

This article explores how dry type transformers improve electrical safety in real-world applications, while also examining how manufacturers like Dingmao (DM) contribute to higher safety standards through engineering expertise, material innovation, and strict compliance with international norms.

Understanding Dry Type Transformers

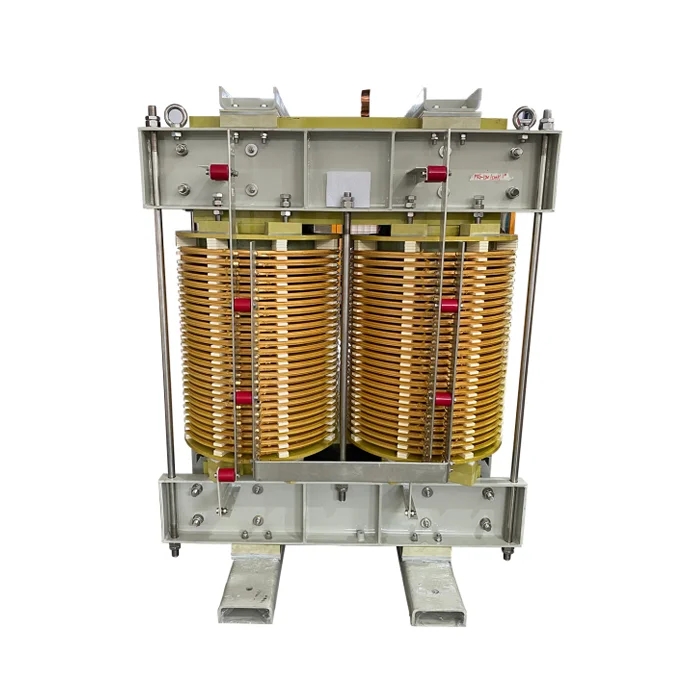

Dry type transformers use air or solid insulation systems instead of liquid dielectric fluids such as mineral oil. The windings are typically insulated with epoxy resin (cast resin transformers) or vacuum pressure impregnated (VPI) insulation. Because there is no oil involved, many of the inherent risks associated with leakage, combustion, and contamination are eliminated.

Dry type transformers are widely used in:

Commercial and residential buildings

Hospitals and data centers

Industrial plants

Renewable energy systems

Underground substations and confined spaces

Their design makes them particularly suitable for indoor installations or locations with strict fire and environmental safety requirements.

Eliminating Fire and Explosion Risks

One of the most significant safety advantages of dry type transformers is their non-flammable construction. Traditional oil-filled transformers rely on insulating oil, which can ignite under fault conditions or high temperatures. Even with protective systems in place, oil leakage or internal arcing can lead to fires or explosions.

Dry type transformers remove this risk entirely:

No combustible liquid insulation

No oil vaporization under fault conditions

Reduced risk of catastrophic fire events

This makes them especially valuable in public buildings, high-rise structures, transportation hubs, and industrial facilities where human safety is paramount.

Improved Safety in Confined and Indoor Spaces

Installing oil-filled transformers indoors often requires additional safety infrastructure such as fire suppression systems, oil containment pits, and reinforced fire barriers. Dry type transformers simplify installation while enhancing safety.

Key safety benefits include:

Reduced need for fire-resistant enclosures

Lower ventilation requirements

Safer operation in basements, tunnels, and enclosed substations

These features help designers and engineers meet building codes more easily while reducing overall system complexity.

Enhanced Thermal Stability and Overload Protection

Thermal management is a critical factor in transformer safety. Excessive heat can degrade insulation, shorten service life, and increase the risk of failure.

Dry type transformers offer:

Stable thermal performance under fluctuating loads

High resistance to thermal aging

Predictable behavior during overload conditions

Modern dry type transformers are often equipped with temperature monitoring sensors that provide real-time data. This allows operators to detect abnormal conditions early and take preventive action before safety is compromised.

Reduced Environmental and Health Hazards

Electrical safety extends beyond equipment—it also affects the surrounding environment and people working nearby. Oil leaks from traditional transformers can contaminate soil and groundwater, creating long-term environmental and health risks.

Dry type transformers avoid these issues:

No oil leakage or disposal concerns

Cleaner operation in sensitive environments

Safer maintenance conditions for technicians

This makes them particularly suitable for hospitals, schools, clean manufacturing facilities, and environmentally regulated zones.

Lower Maintenance-Related Safety Risks

Maintenance activities are one of the most common sources of electrical accidents. Dry type transformers reduce maintenance-related risks by design.

Compared with oil-filled units, they:

Require fewer inspections

Eliminate oil testing and replacement

Reduce exposure to hazardous materials

Technicians can perform routine checks with less risk of burns, chemical exposure, or accidental spills, contributing to a safer working environment over the transformer’s lifecycle.

Manufacturing Quality and Safety Standards Matter

While dry type transformers offer inherent safety advantages, their performance depends heavily on design quality, materials, and manufacturing processes. This is where experienced manufacturers play a crucial role.

Dingmao (DM) is a family-owned integrated manufacturer with roots dating back to 1970 in Taiwan. Over decades, DM has built a strong reputation in the energy industry by focusing on engineering discipline, material quality, and customer satisfaction. From transformer cores and active components to complete transformer systems, DM’s products are designed and manufactured to meet—and often exceed—international standards.

DM’s early collaboration with GE Prolec in producing amorphous steel cores for distribution transformers laid a strong foundation in advanced core technology. As market demand expanded, DM strategically increased its investment in mainland China, transferring mature transformer manufacturing know-how from Taiwan. This move not only improved production efficiency but also enhanced quality consistency while reducing overall manufacturing costs.

Precision Core Design for Safer Operation

Transformer cores directly influence efficiency, heat generation, and long-term reliability. Poor core design can lead to excessive losses, vibration, and overheating—each a potential safety concern.

DM specializes in high-quality transformer cores, including amorphous and silicon steel cores, designed to:

Minimize core losses

Reduce operating temperature

Improve overall system efficiency

Lower heat generation means reduced stress on insulation systems, which directly contributes to safer and more stable transformer operation.

Compliance with International Safety Standards

Electrical safety is governed by strict global standards. Dry type transformers must comply with multiple international regulations related to insulation class, fire resistance, dielectric strength, and mechanical stability.

DM designs its transformer products in accordance with recognized international standards and continuously aims to exceed baseline requirements. This commitment ensures:

Reliable insulation performance

Consistent quality across production batches

Long-term operational safety in diverse environments

Such compliance is critical for customers deploying transformers in cross-border projects or regulated industries.

Application-Specific Safety Solutions

Not all operating environments present the same risks. Industrial plants, commercial buildings, and renewable energy systems each have unique safety challenges.

DM addresses this by offering application-focused dry type transformer solutions, optimized for:

Load variability

Ambient temperature conditions

Installation space constraints

For readers interested in technical specifications and application options, more information on DM’s dry type transformer solutions can be found here:<a href="https://www.dmtransformer.com/dry-type-transformers.html">dry type transformers</a>

This flexibility allows system designers to select transformers that not only meet electrical requirements but also enhance overall site safety.

Supporting Long-Term Electrical Safety

Electrical safety is not a one-time achievement—it must be sustained over decades of operation. Dry type transformers support this goal through:

Durable insulation systems

Stable performance over time

Reduced risk of sudden, high-impact failures

When combined with high-quality manufacturing and proper system integration, they become a reliable foundation for safe power distribution.

www.dmtransformer.com

Dingmao (DM)